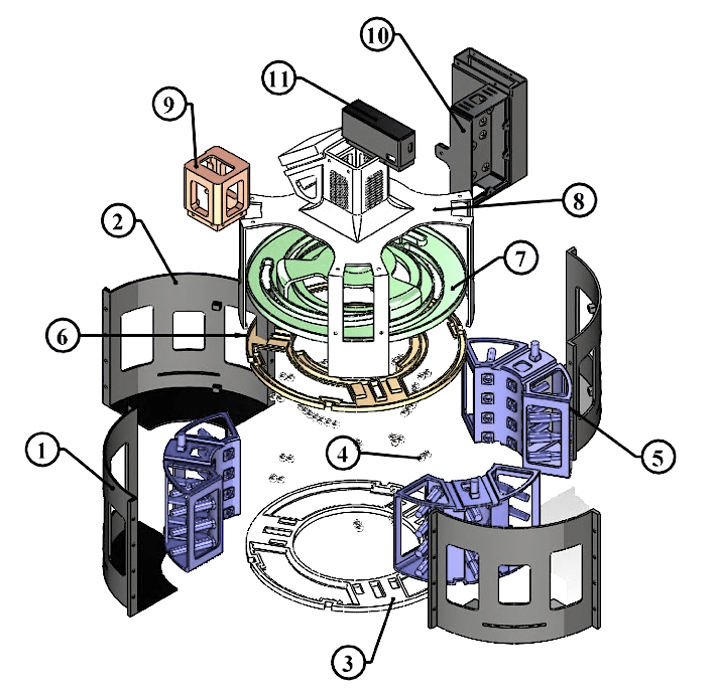

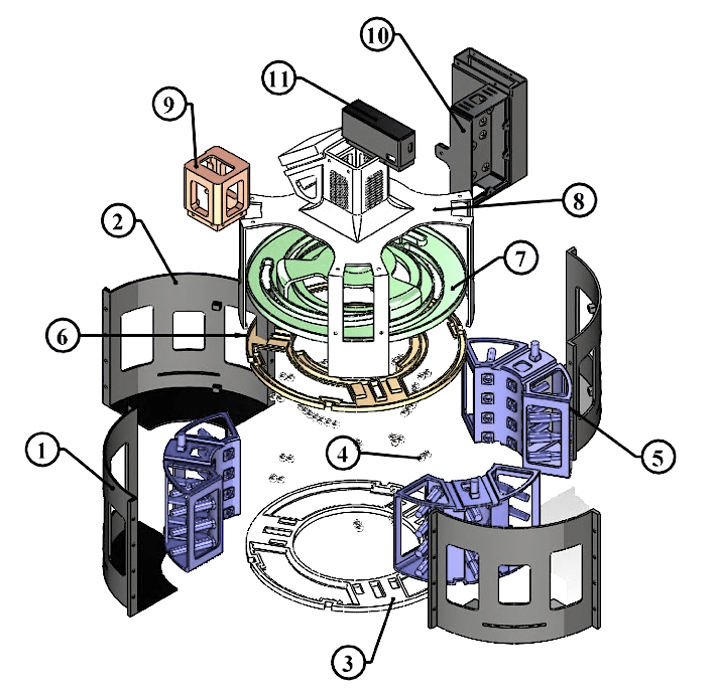

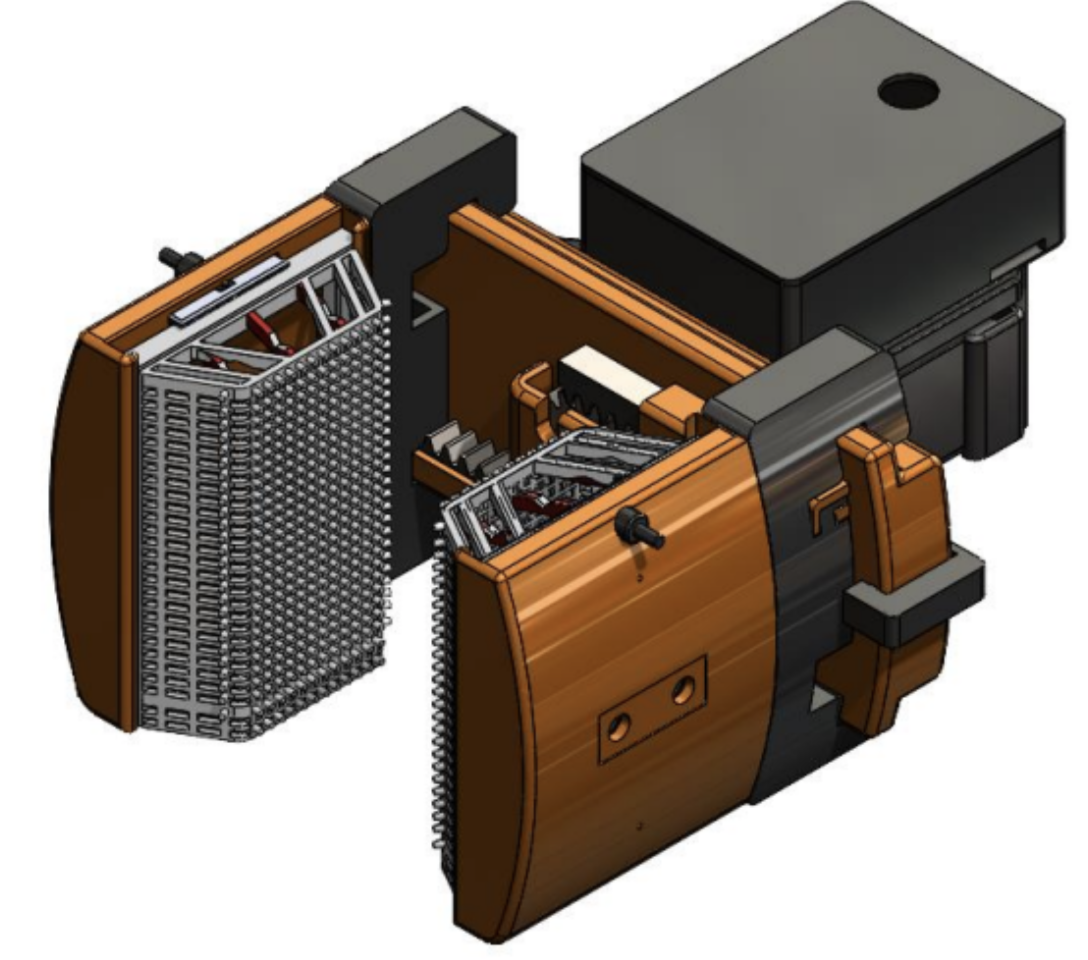

Novel Rotary Mechanical Gripper

Novel mechanical robotic end-of-arm tool for grasping various-shaped objects with both Force-closure and Form-closure grasping.

- Brainstormed and imagined the concept of the gripper inspired by the camera's shutter.

- Designed CAD models of the components using SolidWorks.

- Improved models using GD&T techniques for assembly.

- Analyzed and applied DFMA and lean principle throughout the process.

- Performed root cause analysis for every visible and possible failure mode.

- Printed the parts using PLA and ABS materials for their light and strong nature which is affordable too.

- Assembled and tested the system using an open-loop stepper motor system.

Publication: Applied Science MDPI

Featured Video

Provisional Patent Application No. 63/514,458

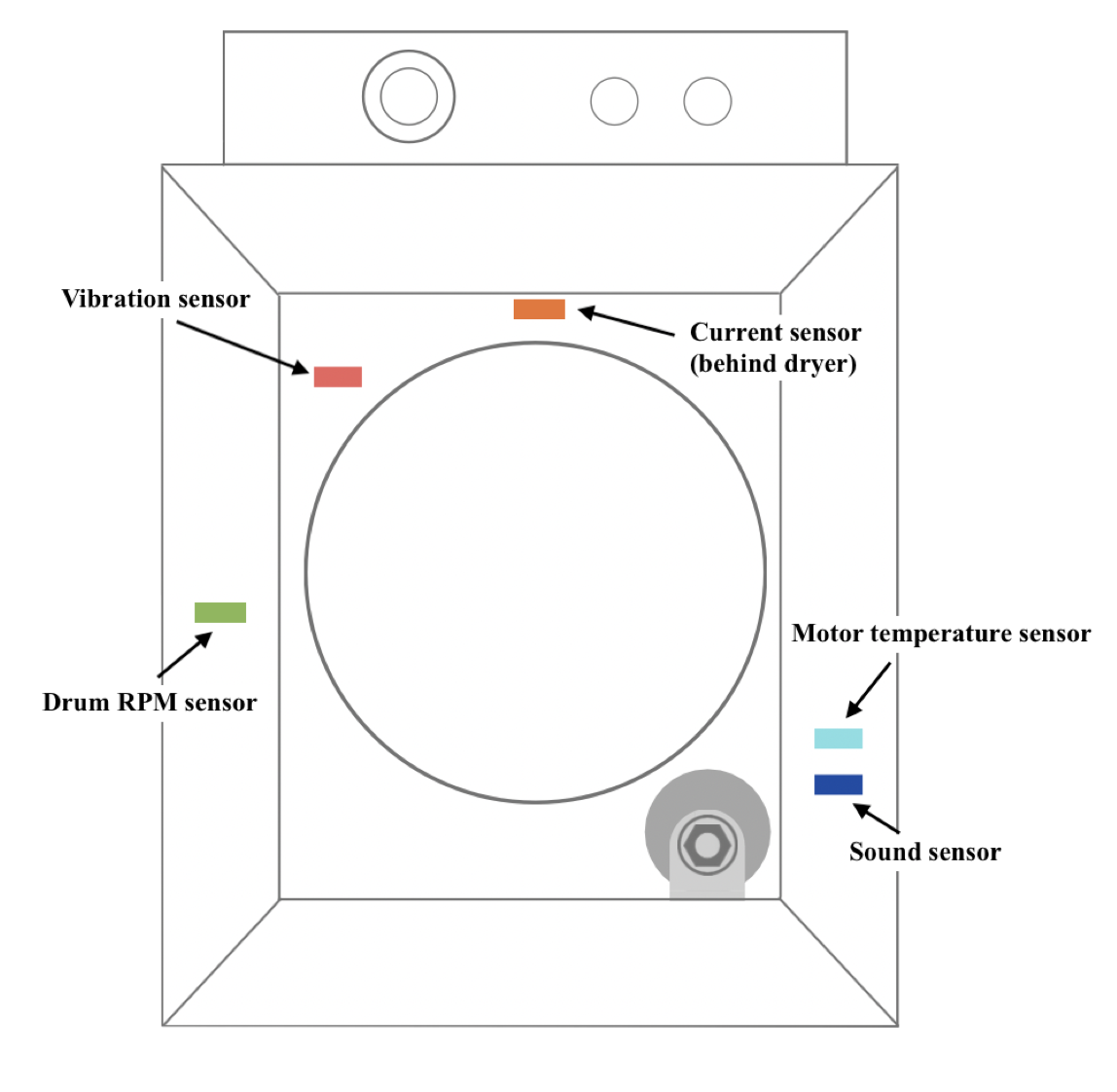

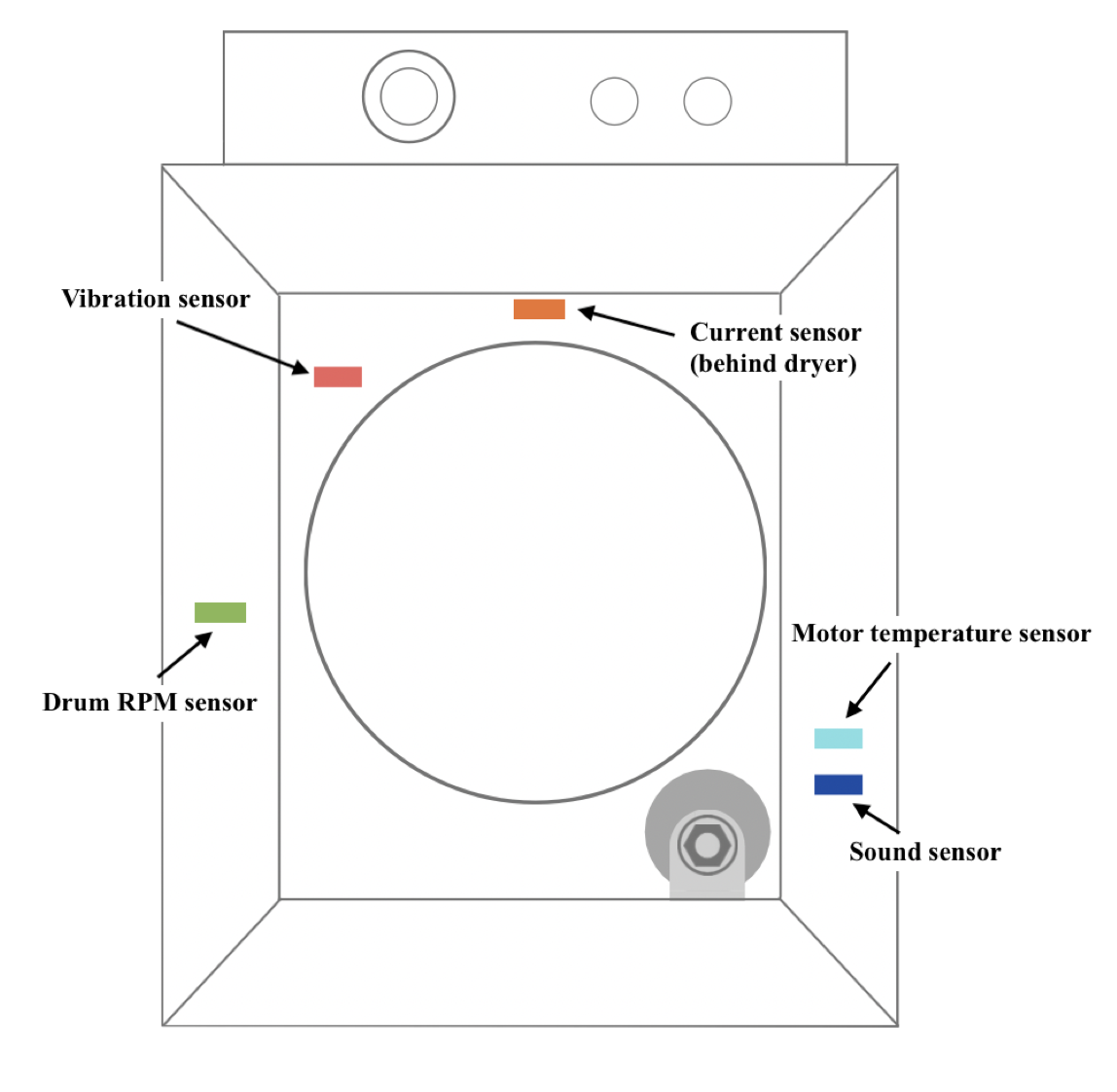

Automated Predictive Maintenance System

An IoT-based predictive maintenance system that detects anomalies in machines to inform about possible machine failure.

- Collaborated with the team in designing the mechanical system required.

- Shortlisted 5 sensors: IR break beam sensor for RPM, IR temperature sensor, DHT sensor, Accelerometer, and Current sensor for power monitoring.

- Implemented all sensors on Raspberry Pi 4, using Python programming.

- Designed and built the custom circuit board on PiHat, soldering wire less than 1 cm.

- Collected and used the data to train the machine-learning model.

Publication: CAINE 2021

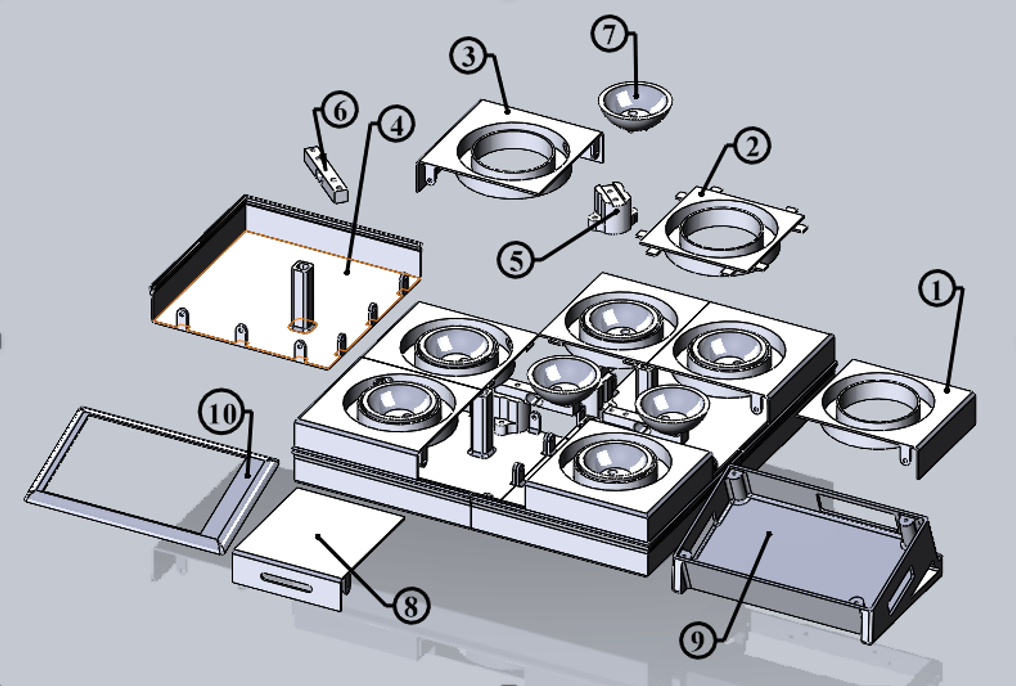

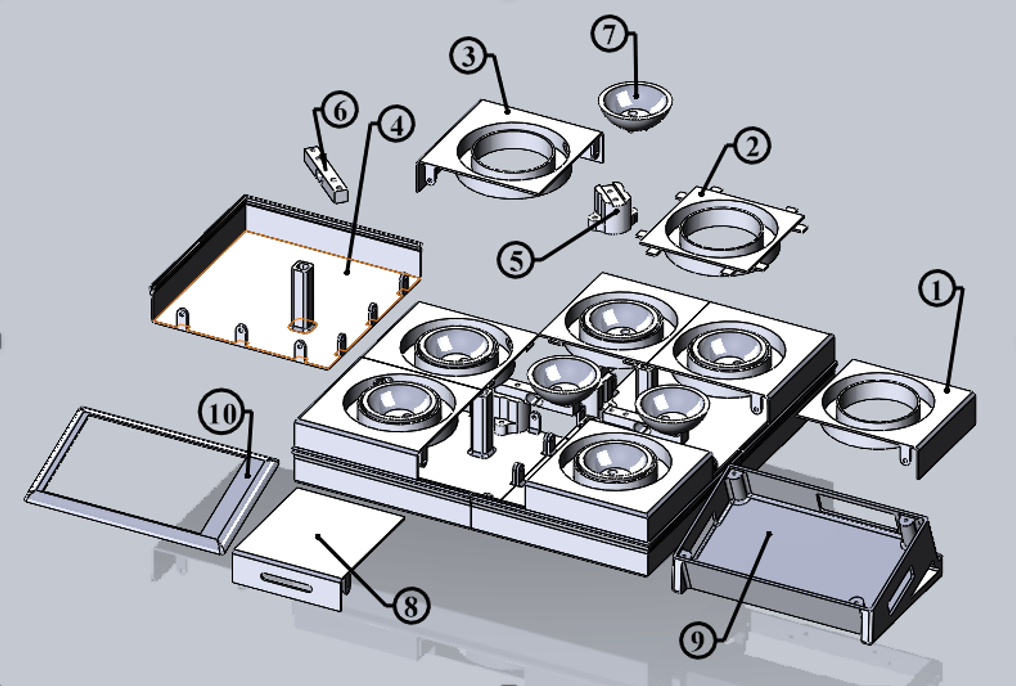

Smart Packaging Palette

Reinforced with image processing and optimization algorithm, the smart palette facilitates customers via customized touchscreen HMI.

- Designed on SolidWorks, using GD&T and DFMA techniques.

- Configured the Arduino-based system for 8 load cells and the touchscreen interface.

- Programmed a multi-layered HMI for load cell's data display, sent input, and view action status.

- Assembled and tested the system.

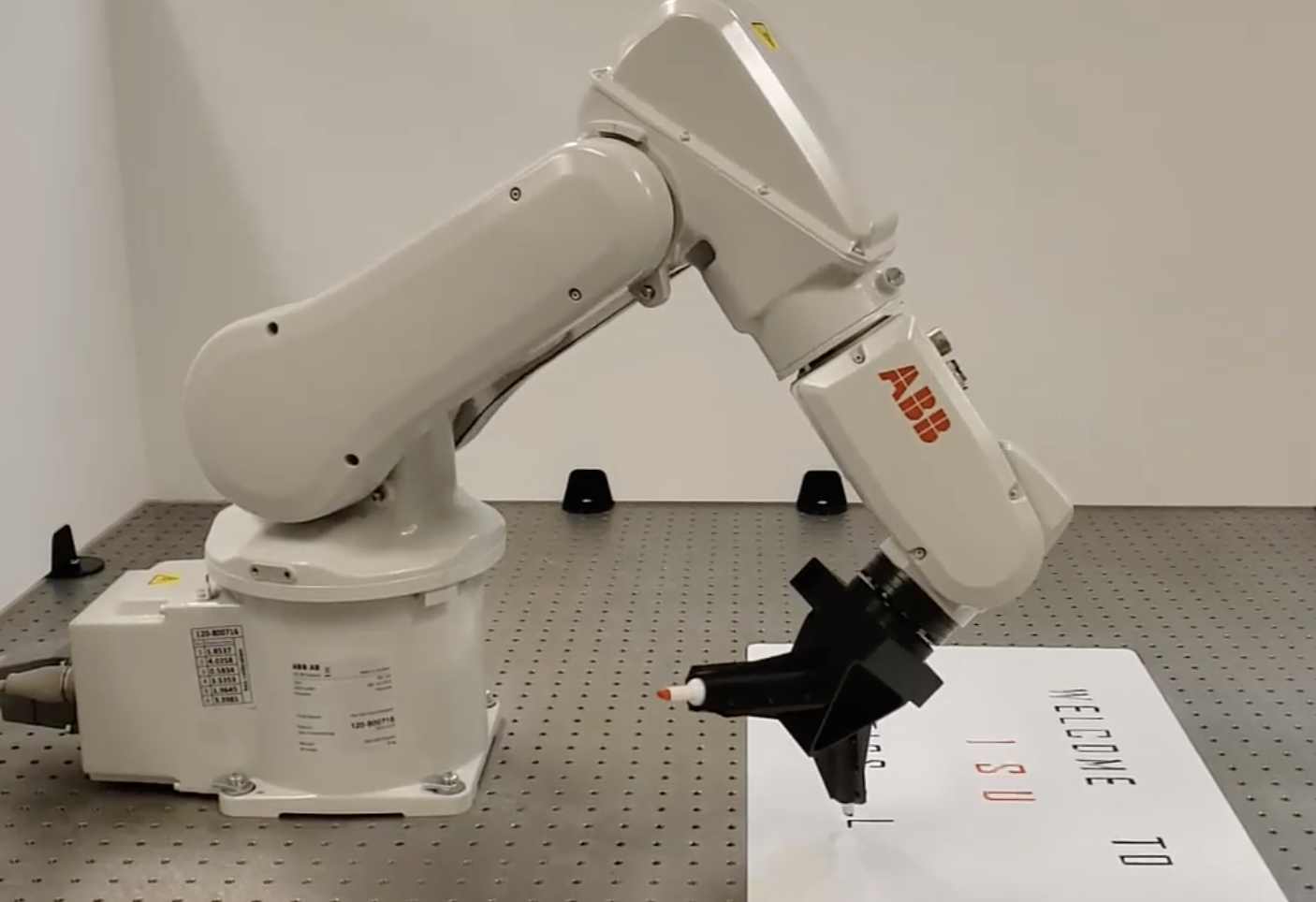

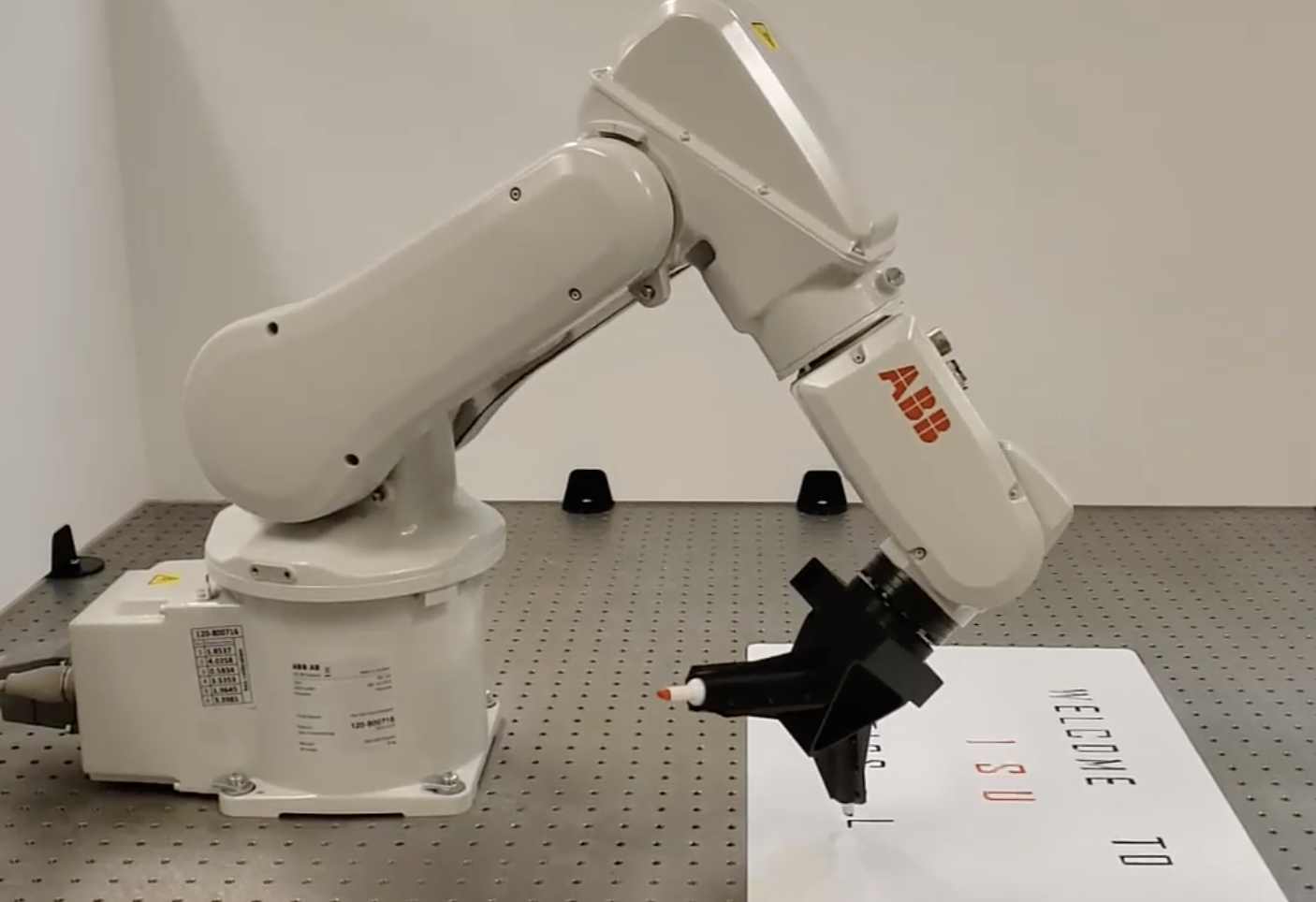

Industrial Robot Programming

ABB Robotstudio-based programming that instructs ABB IRB120 to welcome ISU Robotics Lab visitors.

- Calibrated all 6 axes of the robotic arm.

- Defined the Robot's workspace.

- Defined the tool center point.

- Defined robotic target points for different action locations.

- Programmed the robot based on all the defined entities, using ABB RobotStudio

Featured video

Compressible soft gripper

A novel grasping mechanism for Force-closure grasping.

Featured video

Publication: Applied Science MDPI

Provisional Patent Application No. 63/514,467

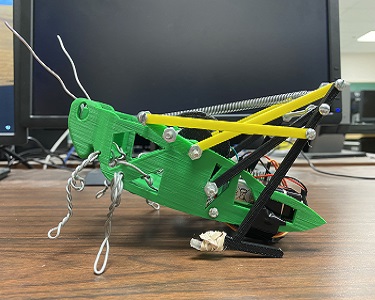

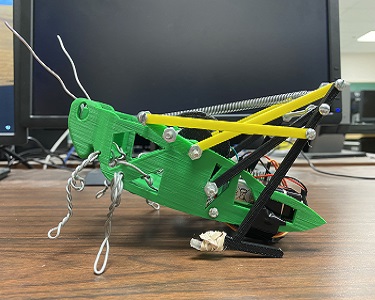

Hopper-Bot

A small robotic resemblance of a grasshopper.

- Designed in SolidWorks and built the prototype using additive manufacturing techniques.

- Inspired by an actual grasshopper, the 5-bar kinematic mechanism is developed.

- Configured an Arduino-based DC Servo motor system for actuation.

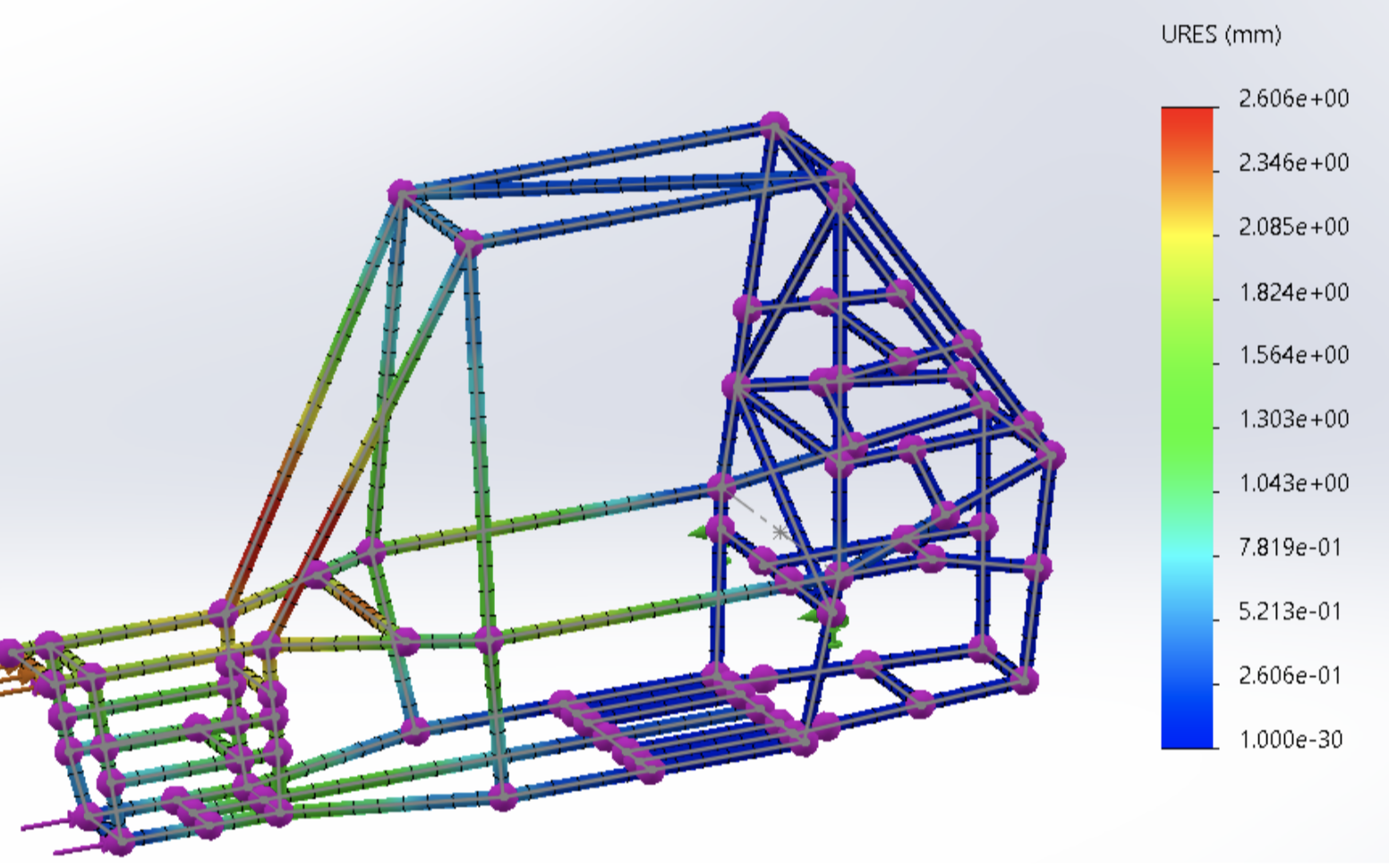

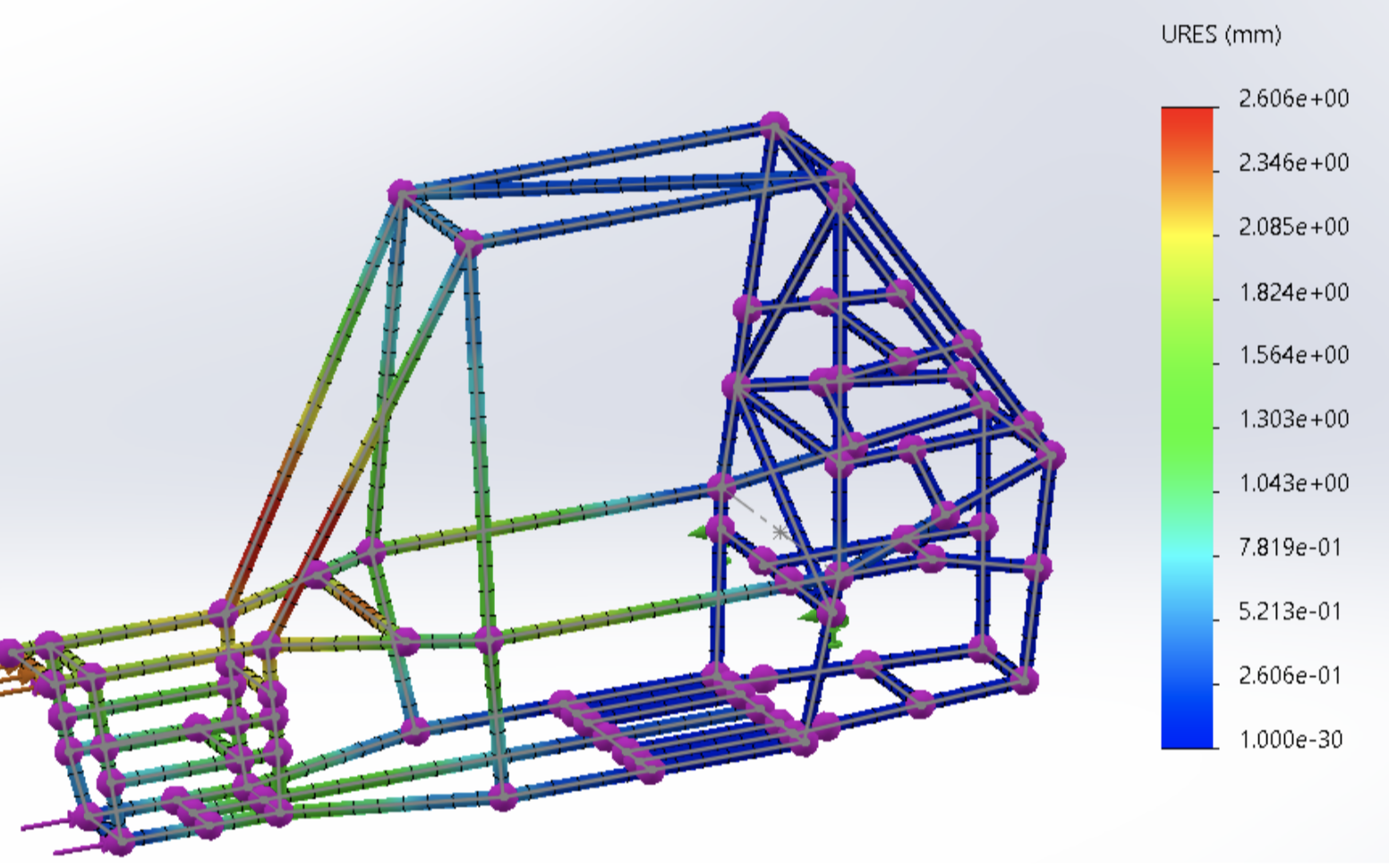

Baja ATV Redesign: RWD to 4WD

Front suspension re-design to accommodate drive shaft.

- Designed and simulated in SolidWorks

- Adjusted caster and camber angles

- Re-positioned shock mounting positions for front suspensions